Add to Cart

Description:

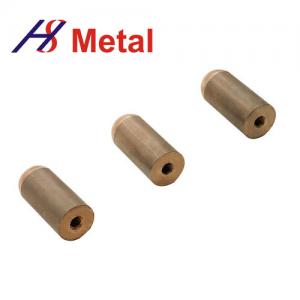

A tungsten copper alloy bar refers to a solid cylindrical bar made from a composite material consisting of tungsten and copper. This alloy combines the exceptional properties of both metals to create a high-performance material with unique characteristics.

Key features and properties of a tungsten copper alloy bar include:

High-Density Construction: Tungsten copper alloys have a high density, making the alloy bar heavy and providing excellent weight-to-volume ratio. This property allows for effective energy absorption and thermal conductivity, making it suitable for applications requiring high durability and heat dissipation.

Excellent Thermal Conductivity: Tungsten copper alloy bars exhibit high thermal conductivity, enabling efficient heat transfer and dissipation. This property makes them ideal for heat sinks, electrical contacts, and components requiring effective thermal management.

Good Electrical Conductivity: While not as conductive as pure copper, tungsten copper alloy bars still offer good electrical conductivity. They can be used in applications where electrical conductivity is required alongside other desired properties, such as high strength or high melting point.

Specifications:

| Material Composition | Tungsten (W) and Copper (Cu) |

| Density | 14.5 - 16.5 g/cm³ |

| Melting Point | Approximately 3,400 degrees Celsius (6,152 degrees Fahrenheit) |

| Thermal Conductivity | 180 - 210 W/m·K |

| Coefficient of Expansion | 6 - 9 x 10^(-6) K^(-1) |

| Electrical Conductivity | 30 - 70% IACS (International Annealed Copper Standard) |

| Elastic Modulus | 250 - 320 GPa |

| Hardness (Rockwell C) | 25 - 30 |

| Tensile Strength | 500 - 1,200 MPa |

| Yield Strength | 300 - 900 MPa |

| Elongation at Break | 5 - 15% |